What is Production Planning?

SAP Production Planning is a critical SAP module. It keeps track of and records the production process flows, such as planned and actual expenditures. Also, the transfer of items from raw materials to semi-finished products.

The process of aligning demand with manufacturing capacity in order to generate production and procurement schedules for completed products and component materials is known as Production Planning

It is fully integrated with SAP, SD, MM, QM, FICO, and PM modules.

Organization Structure in SAP Production Planning

Locations of manufacturing plants and storage within the plants should be available in any live Production Planning module.

Importance of Plant and storage locations in Production Planning-

- At the Plant level, all Production master data is created.

- Planning activities are also carried out at Plant level.

- Production Confirmation process and related goods movement occur at Plant and storage location level.

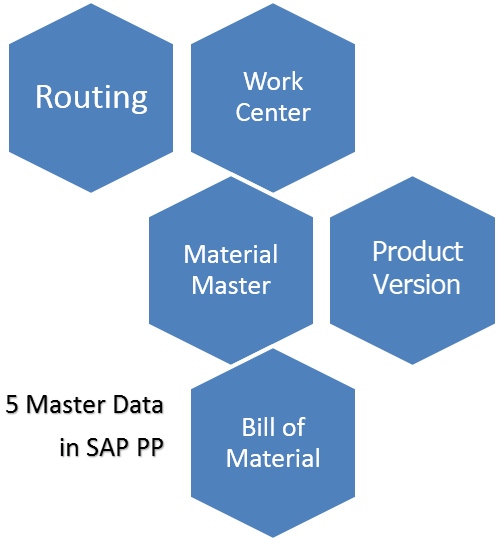

Master Data in SAP Production Planning

Master data is generally static for any company and is very rarely changed depending on the requirement. There are 5 master data to be maintained in the Production Planning module.

1)Material Master

The Material Master records all of the materials that a corporation purchases, manufactures, stores, and sells. It’s a number that identifies a material master record and, by extension, a material.

Materials with similar basic characteristics are grouped together and assigned to a material kind, such as completed or raw material.

It is used for the following purposes:

- To purchase materials.

- In invoice verification for posting invoices.

- For Goods Movement postings such as goods issue or receipt in inventory management and also for physical inventory postings.

- In sales and distribution for sales order fulfillment process.

- In production planning and control for material requirements planning, scheduling, and production confirmation process.

2)Bill of Material(BOM)

A bill of material is a detailed, formally structured list of all the components needed to make a product or assembly, as well as the amount necessary.

BOM’s are used in the planning of material requirements and the costing of products.

For a single product, you can build up to 99 different BOMs.

You can develop a Super BOM for products with variants, which contains all conceivable types of components required to make various sorts of variants, and the suitable component is selected based on the characteristic indicated in the sales order.

For example, the Product Cycle can have a variety of frames (in various colors and sizes), and the appropriate frame is picked in the production order based on the color and size selected in the sales order.

3)Work Center

A Work Center is a machine or group of machines where production operations are performed. Work centers are used in task list operations (Routings).

It contains the data for

- Scheduling

- Capacity

- Costing

4)Routing

Routing is a series of operations carried out at the Work Center. It also provides the machine time, labor time, and other parameters for operations execution.

It is also employed in the typical cost calculation of the product and for scheduling operations.

5)Product version

The production version is a combination of BOM and Routing data for production. It’s interconnected between BOM & Routing and determines the manufacturing process.

There can be multiple production versions as per different manufacturing processes to produce the product.

SAP Production Planning Process Flow

Production Planning process flow typically consists of two. They are:

1. Planning

In most cases, production planning is based on a budgeted sales strategy. Planning is done in accordance with the sales plan in order to achieve sales requirements within the production process flow. Demand for the Product is entered as a planned independent requirement through demand management (PIR). This data from demand management becomes the input to Material requirement planning (MRP). Using master data such as Bill of Material (BOM) and current plant stocks, MRP checks for the availability of various raw materials utilized in production at various stages.

Purchase requisitions are established for goods that are extremely procured, and planned orders are created for materials that are manufactured in-house.

These purchase requisitions and planned orders initiate the Procurement Cycle and the Execution Cycle of Production respectively.

As MRP works with infinite capacities, capacity leveling must be done in order to avoid any capacity bottlenecks.

2. Execution

These planned orders are transformed into production orders and arranged according to production schedules using master data like routings.

On the shop floor, the Production Supervisor releases Production Orders, and material availability checks can be performed to see whether there are any missing components.

Production is carried out according to the actions recorded in the Routing, which includes master data such as Work Center for each activity.

Following the completion of manufacturing, order confirmations are issued, and goods movement for material consumption and goods reception are recorded against the order. As a result, the order is marked as Delivered (DLV), and the material is delivered to the selected storage location.

Usually, at the month-end before doing order settlement, the production order needs to be set to technically completed status in order to calculate production variances by the controlling personnel.

Key Features and Functionality

Material Requirements Planning (MRP)

SAP PP’s MRP functionality ensures that materials are available at the right time and in the right quantity for production. It analyzes demand, inventory levels, and lead times to generate procurement proposals, helping manufacturers avoid stockouts and excess inventory.

Capacity Planning

Effective capacity planning is crucial for optimizing resource utilization and meeting production targets. SAP PP offers capacity planning tools that allow businesses to determine their resource requirements, identify bottlenecks, and allocate resources efficiently.

Production Scheduling

With SAP PP, manufacturers can create detailed production schedules based on demand forecasts, available resources, and production constraints. The system considers factors such as machine availability, labor requirements, and setup times to optimize the sequence and timing of production orders.

Shop Floor Control

SAP PP’s shop floor control capabilities enable real-time monitoring and control of manufacturing operations. It provides tools for recording production data, tracking work progress, and managing deviations from the planned schedule. This feature empowers businesses to respond quickly to changes and maintain a high level of production efficiency.

Benefits of SAP Production Planning

Improved Efficiency and Productivity

By integrating and automating key production processes, SAP PP eliminates manual tasks, reduces errors, and enhances overall operational efficiency. Manufacturers can optimize resource allocation, minimize downtime, and increase output, leading to improved productivity and reduced costs.

Enhanced Demand Planning and Forecasting

Accurate demand forecasting is critical for efficient production planning. SAP PP offers sophisticated demand planning tools that leverage historical data, market trends, and customer insights to generate reliable demand forecasts. This enables businesses to align their production capabilities with customer demand and avoid overproduction or stockouts.

Streamlined Inventory Management

SAP PP’s MRP functionality ensures optimal inventory levels by calculating material requirements based on demand forecasts and lead times. It helps businesses avoid excess inventory, reduce carrying costs, and improve cash flow. Moreover, integrated inventory management features enable real-time visibility into stock levels and movement, facilitating effective inventory control.

Real-time Data and Analytics

SAP PP provides real-time visibility into production data, allowing manufacturers to monitor operations, identify bottlenecks, and make informed decisions. The system offers comprehensive reporting and analytics capabilities that enable businesses to track key performance indicators, analyze production trends, and identify areas for improvement.

Conclusion

In today’s competitive manufacturing landscape, businesses need robust solutions to optimize their production processes and stay ahead of the curve. SAP Production Planning (SAP PP) offers a comprehensive suite of tools and features that enable efficient production planning, resource optimization, and improved productivity. By leveraging SAP PP, manufacturers can streamline their operations, enhance customer satisfaction, and achieve operational excellence in an increasingly dynamic industry.

Investing in SAP PP can provide businesses with a strategic advantage, enabling them to adapt to changing market conditions, drive cost savings, and deliver high